Pound for pound, the spokes in a spider’s web beat steel fibers on all counts. “Dragline” silk is stronger (has better tensile strength) and is obviously better at stretching than steel. If fabric could be made from spider silk, body armor would be more protective and parachutes would be lighter and their cords stretchier. Medically, sutures made of spider silk could be thinner and stronger, and have low immunogenicity.

Photo by Charles J. Sharp

But spider farms for harvesting silk don’t exist because spiders are territorial and cannibalistic. A garment made by human ‘milking’ millions of spiders in Madagascar has been displayed in several museums, but this method is obviously not a commercial possibility.

Therefore, for decades materials scientists have been trying to make a synthetic spider silk that can duplicate the real thing.1 Scientists, for example, succeeded by genetic manipulation to have one kind of spider silk secreted into goat milk. Unfortunately, the actual amount of silk produced was too low to be commercially viable.

Scientists have been able to manipulate bacterial cultures to manufacture foreign proteins for about 50 years. Pharmaceutical human insulin is a primary example of successful commercial use of this process.

Recently, Washington University scientists produced a synthetic spider silk that is very close in its properties to the real thing by genetic engineering of bacteria. For example, if a fiber of natural spider dragline silk and a fiber of the same cross-sectional area made from their synthetic silk were both tied onto a horizontal bar, the same amount of weight could be hung on both of them before each would break from the stress. Likewise, if you took the same fibers and tied them to parallel bars as shown in the photo, both could be stretched to approximately the same distance.

The secret to graduate student Christopher Bowen’s success in Dr. Fuzhong Zhang’s lab was building on previous work from Korea showing that length of synthetic spider silk molecules is correlated with strength.

Bowen was attracted to the spider silk project because of an interest in making materials that are not based upon petrochemicals. If the manufacture of dragline silk in bacterial cultures can be scaled up, this synthetic fiber could be quite valuable commercially. It could be made into fabrics much like nylon.

How they do it?

This section contains biochemical terms. Skip it if it seems too technical. Really!

Christopher Bowen set out to double the size of previous synthetic silk molecules.First, he made a DNA template to be used by his bacterial cultures, based on the amino acid sequence of the silk from the golden orb spider N. clavipes. The silk protein molecule called a “spidroin” consists of repeated short sequences of amino acids. Bowen chose a repeated sequence of 35 amino acids to be strung together like beads 96 times. That was about 3000 amino acids specified by the DNA, and is at the very limit of a foreign DNA template that the bacteria could handle.

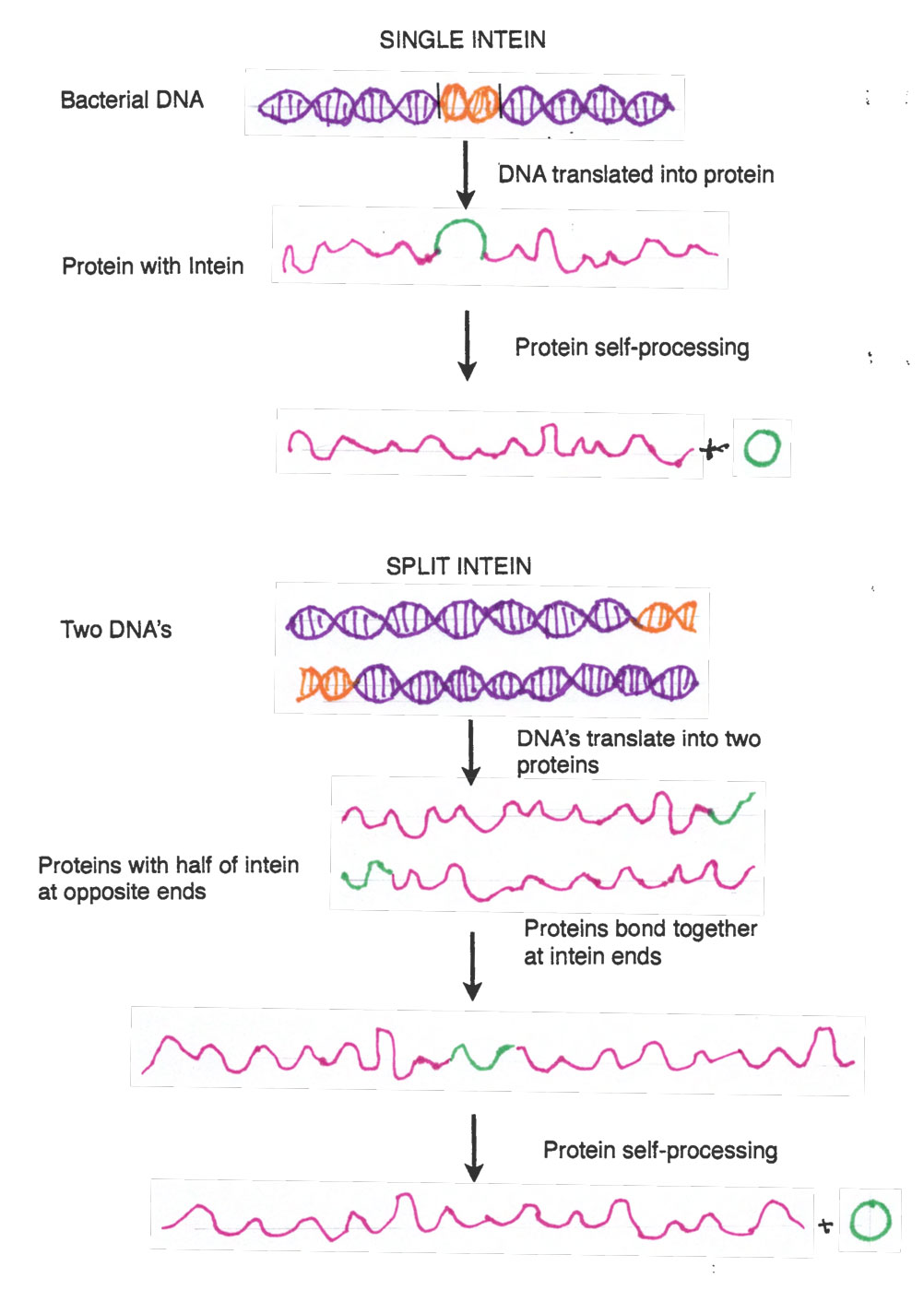

Then Bowen used a clever molecular biology trick, using a piece of bacterial DNA called the “split intein.” An “intein” in the middle of a DNA sequence, when translated into a protein, will actually fold back onto itself, cut itself out of the protein, and in the process link the cut ends of the remaining protein to each other. A split intein goes a step farther. One half is fused to the end of one protein chain to be linked, and the other half is fused to the beginning of another protein chain. When the halves meet, they join up to form a whole intein. Then the intein folds up, splits itself out and links the two proteins. Isn’t nature amazing?

So Bowen’s intein linked protein is now 6,000 amino acids long—even longer than the spider silk protein molecule that occurs in nature. When purified by a rather long series of biochemical manipulations and forced through a syringe with a tiny hole, a very realistic ‘spider silk’ fiber has been manufactured. The fiber consists of molecules bonded to each other longitudinally by chemical bonding beyond the scope of this blog.

So Bowen’s intein linked protein is now 6,000 amino acids long—even longer than the spider silk protein molecule that occurs in nature. When purified by a rather long series of biochemical manipulations and forced through a syringe with a tiny hole, a very realistic ‘spider silk’ fiber has been manufactured. The fiber consists of molecules bonded to each other longitudinally by chemical bonding beyond the scope of this blog.

Comparing Synthetic to the Real Thing

The spider is much more efficient than the laboratory so far. Dragline silk in the living spider is soluble in water up to a concentration of 50%. Bowen’s silk is insoluble in water, and has to be spun out of a dilute solution of alcohol.

And the spider can make 6 other kinds of silk, with different properties. Dragline silk forms the spokes of the web, and is also used when the spider dangles by a string. The spirals attached to the spokes are a different silk, and are coated with a glue silk. Prey caught in the web is wrapped in yet another silk, and that silk is also used to insulate the spider’s egg case. The eggs have yet another silk for their outside case. The web is attached to surfaces and reinforced with a cement-like silk.

Using biology for solving problems

Spider silk from the laboratory is just one example of what is termed ‘biomimicry.’ Over the very long course of evolution, nature has devised solutions to all kinds of problems and conditions that living things encounter.

One of the best examples of successful biomimicry is Velcro. A Swiss engineer, George de Mestral, channeled his annoyance at the burrs stuck to his clothing after a hike into curiosity about how these burrs work. He looked at the burrs under a microscope, saw that they were hooks that could attach to the fabric loops in his clothing—and an industry was born. Velcro is made from nylon, not plant material, but it works in the same way.

Biomimicry can also be a process. For example, careful study of water-skimmer bugs that seem to walk on water led to the design of robots that could walk on water using the same principles. Study of cockroach locomotion has been duplicated in very fast-moving robots.

Obviously, biologists study how living things work out of curiosity. But observations and careful analysis can lead to applications. Could there be a better argument for the preservation of species?

1. Peter Parker, aka Spiderman, learned how to make his own spider silk. It was quite a Marvel-ous invention.

This is the third in a series of self-published articles. To get an email whenever there’s a new blog post, use the Subscribe form in the left sidebar.

Have a topic you’d like me to explore? Use the Contact Me link in the left sidebar.

You taught me a lot about silk. But I really want to see a robot walk on water.

If I don’t see you on Monday, have a safe and fun trip.

This is interesting, Jo, and,as promised, an easy read.!i even skimmed the technical part. I was most interested in the idea of substituting biological material for petroleum based material.

Interesting piece, thanks!